The structure of high-voltage cables

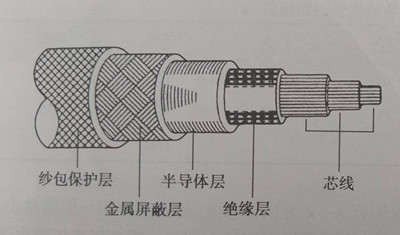

Since the high-voltage generating device and the X-ray tube device of the large X-ray machine are separated, there is no contact between the two, so it is necessary to rely on the high-voltage cable to connect the two so that the high voltage generated by the high-voltage generating device can be transmitted to the X-ray The two poles of the tube, and the filament heating voltage is delivered to the cathode part of the X-ray tube. Due to the different distribution positions of core wires in high-voltage cables, high-voltage cables can be roughly divided into coaxial high-voltage cables and non-coaxial high-voltage cables. The following is the structure diagram of coaxial high voltage cable and non-coaxial high voltage cable:

The specific structure of coaxial high voltage cable includes sandbag protective layer, metal shielding layer, semiconductor layer, insulating layer, core wire and other structures.

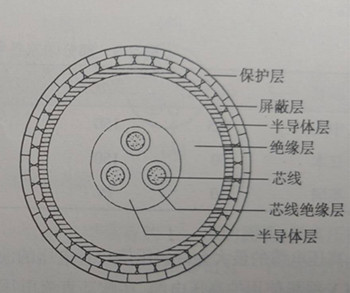

(Non-coaxial high voltage cable)

Due to the problem of its manufacturing and processing technology, the application range of non-coaxial high-voltage cables is relatively wide. The specific structure of non-coaxial high-voltage cables and conductive core: conductive core is the innermost structure of high-voltage cables, different high-voltage cables There are also differences in the number of cores. The number of cores is generally divided into two cores, three cores, and four cores. Each core is made of many strands of copper wire and covered with insulating rubber. Two-core high-voltage cables are used for single-focus X-ray tubes, and three-core high-voltage cables are used for double-focus X-ray tubes. Four-core high-voltage point cables are used for three-stage X-ray tubes.

High voltage insulation layer: The main function of the high voltage insulation layer is to insulate the high voltage of the core from the ground. The main material is natural rubber, located on the outside of the core. The high-voltage insulating layer requires good mechanical strength and toughness, so the high-voltage insulating layer can be bent within a certain range.

Semiconductor layer: The semiconductor layer can ensure the insulation performance of its high-voltage insulation layer. Because there is an electrostatic field between the outer surface of the insulation layer and the shielding layer, and the semiconductor layer has semiconductor properties, placing it on the outside of the high-voltage insulation layer can effectively prevent The electrostatic field discharges, thereby ensuring the insulation performance of the high-voltage insulation layer.

Metal shielding layer: The metal shielding layer mainly plays a role of safety protection. The role of the metal shielding layer is mainly to prevent the high voltage of the conductive wire core from harming the safety of the operator when the high-voltage cable is broken down. Because the conductive wire core and the metal shielding layer are short-circuited, the metal shielding layer is connected to the ground through the fixed ring The connection protects the safety of the operator and the subject to a certain extent.

Protective layer: The main function of the protective layer is to protect high-voltage cables and reduce damage to them caused by external environmental and conditional factors.

If you are interested in our products, please feel free to contact us info@xraycable.com!